Categories WikiBlog Pfeifen_Wiki The Pipe Finish

The Pipe Finish

The surface of a pipe can be finished in many different ways. Basically, the nature of the pipe can be divided into 3 basic finishes:

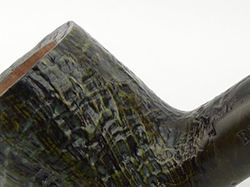

Rustication:

During rustication, the wood is roughly processed. Suitable tools are Dremel, rasps, files, nails and more. This gives the pipe an individual look. Either evenly rusticated, for example with notches, grooves and furrows, or specifically for decoration with ornaments. Rustication is often used when the wood is of excellent quality, but is visually less appealing due to dirt inclusions, cracks or defects. In these places, the wood is rusticated and the visual blemish disappears. The rest of the beautiful grain is preserved.

Sandblasting:

Sandblasting is done before pickling. The fine sand radiates the soft parts of the wood, while the harder parts are less worn away. Therefore you can still see the grain of the pipe after the treatment. Faulty areas also remain visible, but are no longer noticeable. A wide variety of end results can be achieved by means of different grain sizes and jet intensities.

In some cases, rustication is combined with subsequent sandblasting. Both lead to an enlargement of the surface, which can then better dissipate the heat to the outside and thus support cool smoking. In addition, these whistle are less sensitive to shocks, for example from falling down.

Smooth:

Here the surface is or remains smooth. Most of the time, it is treated further, since you can see little of the structure and grain of the wood in the light-colored wood of the briar. This can be done, for example, by using oil. An unstained, only oiled pipe is usually free of faulty wood, as any correction would immediately become unattractively visible. Pickling is usually done to give the pipe a colour. Dirt inclusions and superficial cracks are leveled with wood putty. In order to cover the putty areas, a stain that is as dark as possible is used. Light stained pipes are in most cases completely free of putty. Then it is sealed with lacquer, carnauba wax or polishing paste.

With lacquered pipes it is important to pay attention to the quality. In the simplest method, the pipe is dipped or brushed. The dense varnish makes it difficult for the pipe to breathe, and the moisture after smoking remains in the wood. This can cause the pipe to rattle. In addition, poorly painted pipes tend to blister because the heat cannot be dissipated. With quality pipes, on the other hand, a breathable, fine high-gloss layer is sprayed on. The pipe smokes and then continues to behave optimally.

In the past, pipes were also covered with a wide variety of materials. A few decades ago there were many pipes sewn into leather. Only a few years ago there was even a series of models covered in denim.